Our Food Packing client at their Indiana facility desired to take the next step from clipboard-meter-reading to centralized data collection.

Flow data was gathered from remotely mounted flow meters using remote Flex I/O on a fiber optic ControlNet Network.

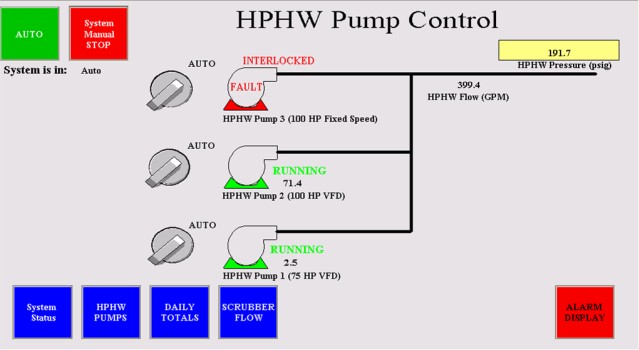

An Allen-Bradley ControLogix PLC was provided for pressure control, pump sequencing and totalization calculations.

RSView32 Graphical screens accessing the PLC data via Ethernet were provided to display: daily totals from the meters, hot water pump control status, scrubber flow rates, alarms, historical trends and system status.

The project included electrical wiring and network design, PLC programming, HMI configuration, start-up, commissioning, training, and data reporting.